Termékek

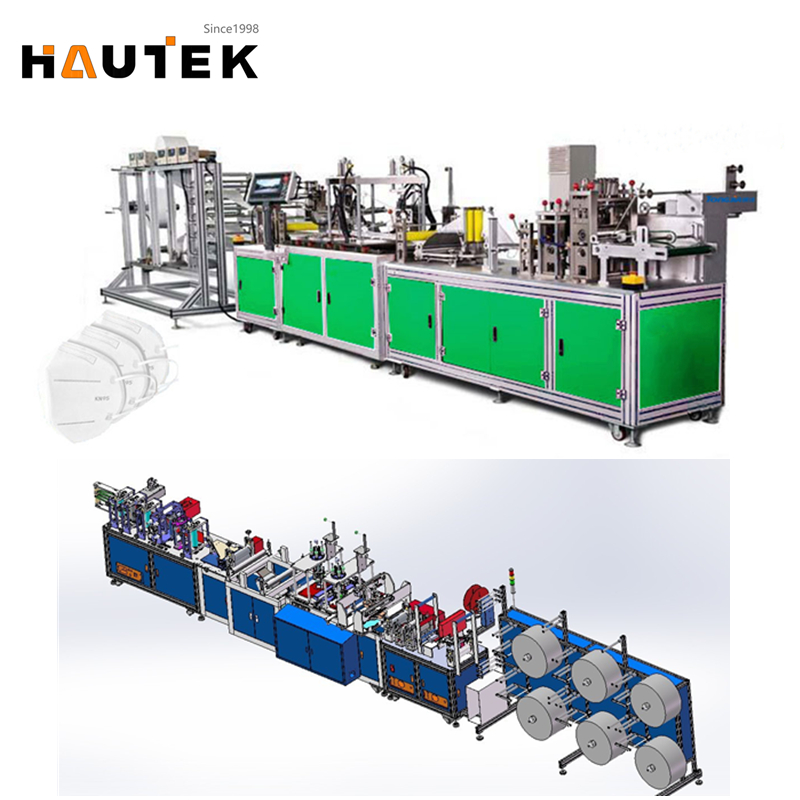

PP Meltblown Nem szőtt gép/gyártósor

A termékek öt előnye

- Az energiafogyasztás tényleges csökkentése

- Automatikus vezérlőrendszerek használata

- Stabil működés

- Támogatott technológia

- Ez a gyártósor vezető szerepet tölt be Kínában.

termék leírás

Ningbo Hautek Import & Export Co.Ltd.

Kapcsolattartó: Frank Huang

telefon: +86-13805862932

Vezetékes: 0574-87317986

Cég címe: 831,No.598 Jiangnan Rd., Ningbo, China P.C.315040.

Weboldal: hautek.infohub2b.com

Előző: KN95 arcmaszk Making Machine/Prod...

Következő: No